Renowned post-modern Dutch architect and urban theorist Rem Koolhaas once said that “infrastructure is much more important than architecture.” When it comes to vertiports, his words ring true.

Images abound of sparkly new vertiport designs, with passengers happily climbing aboard electric vertical take-off and landing (eVTOL) vehicles from attractive and efficient facilities. But unless these vertiports have the necessary electrical and digital infrastructure, they are unlikely to fulfil the promise of the new urban air mobility (UAM) revolution.

“A vertiport’s digital and electrical infrastructure will differ significantly from that of a small airport due to the unique characteristics of VTOL operations,” explained Amit Ganjoo, founder and CEO of Washington DC-based ANRA Technologies, which has developed a vertiport management system (VMS) – a software platform designed to seamlessly connect various systems at the facility.

Both the aircraft and location require different systems to those used for conventional airports

According to Ganjoo, top of the list is the charging infrastructure required to support eVTOLs: “Vertiports designed for eVTOL aircraft will necessitate advanced charging infrastructure to accommodate the electric propulsion systems of these vehicles. This includes high-capacity charging stations, battery swapping or rapid recharging capabilities and sophisticated energy management systems. Vertiports must be able to simultaneously charge multiple aircraft quickly and efficiently in order to minimise downtime.”

Vertiports will also have very different digital requirements: “The digital infrastructure must support low-altitude air traffic control for the co-ordination of multiple short-distance flights within urban environments. Additionally, vertiports will require seamless integration with ground transportation networks, efficient passenger and cargo handling facilities and noise reduction measures to address the challenges posed by urban operations.”

“We see the core differences stemming from layout, space constraints and usage patterns,” said Cory Cozzens, co-founder of Altaport, which is developing a ground infrastructure platform for advanced air mobility (AAM). “Differences are too many to list, but a good example is the need for resource scheduling and permission management. Very few GA [general aviation] airports – and today, heliports – are space-constrained, so very few are prior permission required [PPR] or otherwise need advanced resource scheduling. The nature of vertiports, including the intent for them to be closer to population or business centres, is such that they will be fairly space-constrained, thus resource scheduling and PPR management becomes critical whereas at today’s United States-based GA airports they are largely irrelevant.”

Furthermore, quick aircraft turnarounds are not common at GA airports, but will be critical at vertiports due to both operator economics and vertiport space constraints. “Features that facilitate those quick turns, including management of chargers as a resource and the availability of fast charging, will be more critical to vertiports than to GA airports,” Cozzens said.

Sustainable, resilient power is crucial for vertiports

Electrical innovation

Stakeholders engaged in the sector are partnering with technology companies and designers experienced in electrical infrastructure to get it right.

Technology and infrastructure specialist Siemens is collaborating with multiple original equipment manufacturers, vertiport designers and vertiport operators on the advancement of the industry, according to John Kasuda, head of airports at Siemens Smart Infrastructure North America. He said: “As vertiport operators plan their networks, Siemens works with them on several key aspects, including sustainable, resilient power, which is imperative. The safe operations of vertiports and their vehicles depends on it.”

Kasuda noted that the electrical requirements of vertiports should not be underestimated: “Vertiports will have a large electrical load. In fact, a vertiport with just two charging stations could require up to 1MW of power – roughly the amount of electricity required to power 750 residential homes simultaneously. The daily operational tempo of a vertiport will produce a unique electrical profile and large variations in demand.” As a result, Siemens is working with vertiport operators to design and deliver small-scale microgrids that will use different forms of renewable energy and energy storage systems to produce reliable, sustainable power to meet load profiles.

The vertiport automation system will manage everything from ground operations to scheduling, passenger management and vehicle charging

Siemens is also sharing its expertise in electric vehicle charging with stakeholders in AAM. Kasuda told Airports International: “Because eVTOL vehicles have battery sizes similar to transit vehicles, many of the charging power requirements are similar. At the industry inception, charging turnaround times for eVTOL vehicles will be slow and can be accommodated with commercially-available charging stations and industry standard cCombined charging system connectors.” As the industry matures and grows, faster vehicle turnaround times will be required, which will increase power requirements to megawatts. At this stage, he explained, the industry standard megawatt charging system standard connector will be required.

Siemens’ data-driven platforms will connect real and digital worlds at vertiports. Kasuda explained: “Via digitalisation, Siemens platforms provide control and metering of power, determine electrical and mechanical assets’ performance and conditions, and create a safe and secure environment for both passengers and vehicles.”

Japanese eVTOL aircraft manufacturer SkyDrive has been working with Kansai Electric Power Company (KEPCO) to develop electric charging facilities ahead of the World Expo 2025 in Osaka, where the SkyDrive 3 eVTOL is one of a number of vehicles set to operate AAM services. SkyDrive and KEPCO are partnering on charging and electric power infrastructure for vertiports in Japan and then worldwide. A spokesperson for SkyDrive said: “We believe that infrastructure facilities including vertiports require improvements in operating ratio – turnaround time – for profitable operation. Therefore, the design of the facility should have easy scalability for electronic mobility, including eVTOLs, in order to increase the usability.”

An effective digital layer is essential for effective vertiport operations

Bespoke solutions

Technology companies are working on comprehensive solutions to meet the ground infrastructure requirements of vertiports. Altaport, for example, is developing a way to combine multiple critical systems into a single modular platform for vertiport operations. According to Cozzens, the company’s vertiport automation system (VAS) will manage all aspects of vertiport operations, including ground operations, scheduling, passenger management and vehicle charging, either directly or through integration with third-party systems.

Altaport has partnered companies across the AAM sector, including 1200.aero, which automates operations monitoring and data services for ground infrastructure, charging specialist Electro.aero and airspace awareness and security company Fortem Technologies. Meanwhile, Moonware is developing solutions to automate ground handling operations, ResilienX has designed software to monitor the health, integrity and performance of complex system of systems and TruWeather Solutions collects and fuses diverse weather data sets for targeted insights. The result is a comprehensive vertiport management solution that incorporates data, including low altitude micro-weather, automatic dependent surveillance-broadcast, foreign object debris detection and airspace incursion sensors at the same time as managing ground-based activities such as vehicle charging and ground support equipment allocation and movement.

The VMS microservice architecture developed by ANRA is aircraft agnostic

Announcements on additional partnerships are imminent, according to Cozzens: “We continue to see meaningful interest in what we’re doing both from vertiport developers and solution providers who are keen on integrating into our system.”

Altaport’s work in AAM has been informed by its automation solutions for more traditional aviation sectors of general aviation and helicopters. Its solution has been deployed to several heliports in Brazil, facilitating thousands of flights since launch in early 2023. Cozzens noted: “We’re continually incorporating learnings from these operations to ensure that we’re developing a solution that can handle high volumes of flights and that is capable of the diversity of physical infrastructure typologies, business arrangements, etc, reflected by helipads and airports today, and which we expect to see reflected by vertiports tomorrow.”

Altaport has also deployed a system at GA airports in the United States to capture further insights: “We are deeply engaged with AAM infrastructure developers, OEMs and other industry participants to make sure we’re adding to the helipad learning insight with additional features and capabilities that will be needed for vertiports.”

The digital layer

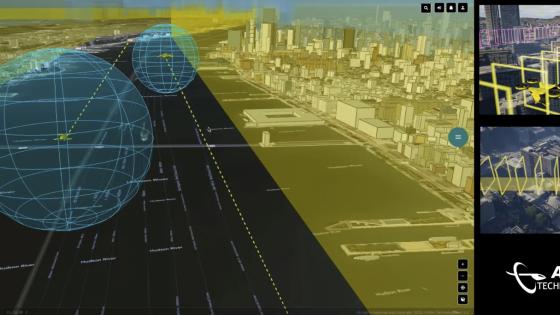

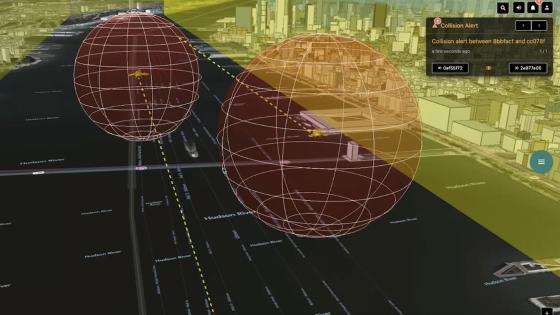

While much of the sector’s focus is on building the physical infrastructure and defining the passenger experience, ANRA’s Ganjoo says his company’s priority is the digital layer required for successful operations. In ANRA’s case, this is its vertiport management system (VMS), which was launched at the 2023 Dubai Air Show. Ganjoo explained: “This software platform facilitates intelligent operational and safety decisions by seamlessly connecting with various systems at the vertiport, in aircraft and the broader AAM ecosystem.”

The VMS microservice architecture developed by ANRA is aircraft agnostic, can support multiple vertiport designs and integrates with existing commercial air traffic management systems, according to the company’s founder. The system supports an operator’s flight operations from pad to pad, with a comprehensive suite of services, including real-time vertiport resource status and reservation requests for landing, resource schedule for vertiport resource availability, reservation and clearance requests for inbound and outbound flights, system checks to verify the status of outbound flights, live telemetry for monitoring aircraft data of inbound and outbound flights, micro-weather services, live surveillance data for nearby aircraft and integration with broader UAM traffic management systems.

Development of ANRA’s solution began after publication of NASA’s High-Density Automated Vertiport Concept of Operations

ANRA’s initial release of VMS is available for use by organisations developing concepts of operation, conducting urban planning, constructing physical vertiport facilities and converting heliports to vertiports, as well as airspace managers seeking to develop their UAM ecosystem. Development of the solution began after publication of NASA’s High-Density Automated Vertiport Concept of Operations and incorporates US FAA and EASA vertiport design guidance.

Having supported NASA, FAA and SESAR research projects, ANRA came to the sector with extensive experience of providing traffic management services for UAM aircraft. Ganjoo explained: “This experience helps ANRA to experience first-hand the technical challenges of enabling fleet operators to conduct safe and efficient operations, which will help mature our VMS platform that seamlessly connects to our airspace management capability and other qualified providers as well. We believe our vision of interoperability and adapting to any market will help expedite commercialisation by enabling increasingly autonomous services sooner.”

ANRA is seeking vertiport development, aircraft OEM and air navigation service partners to use its VMS for testing and evaluation. It has already partnered with NAVOS Air, which is the first company in the US to receive FAA conditional approval for a vertiport. Ganjoo revealed that ANRA was also due to demonstrate VMS with an unnamed partner at the Consumer Electronics Show (CES) in Las Vegas, in January 2024. It is also negotiating to deploy VMS in several locations, with more information to be revealed at CES.

Development of ANRA’s solution began after publication of NASA’s High-Density Automated Vertiport Concept of Operations

These are early days for UAM, with VMS due to be updated with more features and capabilities to meet future requirements and standards. Ganjoo noted: “We fully recognise at this stage in the industry there is much more work to be done, so VMS is designed to remain compliant with maturing regulations and to evolve with technology as aircraft, supplemental data providers and airspace systems continue to propel the UAM ecosystem.”

Automation and collaboration

The digital infrastructure at a vertiport will be significantly different to that of a traditional airport, with the focus on automation, according to Aaron Erwin, sales engineer at technology solution provider Firstco. The company is drawing on its wide experience across the transportation, defence and automation sectors in the development of its VMS, which will enable the remote management of a distributed vertiport network from a single interface.

Erwin explained: “The Firstco VMS allows infrastructure operators to manage multiple vertiports from a single command and control centre providing operators with situational awareness, software assisted operations and teleoperations.” The teleoperations functionality of VMS will allow operators to remotely manage vertiport infrastructure efficiently and safely from a remote-control centre, avoiding the need to be physically present at each location.

Firstco’s VMS supports the seamless integration of multiple systems, providing enhanced situational awareness and allowing operators to make insightful decisions in real time. Such systems include high- and low-voltage power distribution, eVTOL charging, weather monitoring, perimeter security, CCTV analysis, airfield ground lighting, landing zone allocation, heating, ventilation and air conditioning, indoor lighting, public address/voice alarms, flight information displays and passenger help points.

Erwin said: “Leveraging our process automation experience, the platform automates repetitive and time-consuming tasks, freeing up operators to focus on higher-value activities. With its intelligent and adaptable capabilities, the platform optimises efficiency, reduces errors and enhances productivity from automated data analysis to task scheduling and execution.”

UK-based Firstco has adopted a collaborative approach to VMS development, with most of its partnerships subject to non-disclosure agreements. According to Erwin: “The emergence of a new form of mass public transport is incredibly rare. Therefore, for AAM to stand the best chance of success, market-wide collaboration is imperative. The market requirements are constantly evolving as AAM concept of operations are developed. Firstco has taken a collaborative approach to understand and help steer this development to ensure we have a fit-for-purpose solution ready for market adoption starting with proof-of-concept all the way through to mass scale.”

Firstco has incorporated learnings from its participation in the UK’s Connected Places Catapult Future of Mobility programme, which saw it working alongside companies including London/Heathrow Airport, Ferrovial Vertiports, GKN Aerospace and the UK Civil Aviation Authority. This work enabled Firstco to take a holistic view of market needs and use it to steer VMS development to help solve some of the fundamental challenges ahead. The company has also built an online virtual control room to allow potential operators to visualise how the system would integrate with their operations. As the VMS is an open platform and agnostic to manufacturer, other systems can be added.

Vertiports will require seamless integration with ground transportation networks

Erwin believes a different approach is required for such a new transportation mode: “For AAM and eVTOLs to become a feasible mode of transport and affordable to the masses, costs will need to be cut and the number of site-based staff will need to be optimised without negatively affecting passenger safety or experience. Vertiport economics will not be able to support on-site operation and maintenance strategies found at traditional airports. Instead, they will need to rely on remote management from a centralised operations room that supervises multiple vertiports.”

FURTHER READING: Green from the get-go

As you would expect in this day and age, sustainability is playing a leading role in AAM infrastructure design and development. “One of the steps in ensuring that the environmental footprint of a vertiport network is sustainable is to accurately understand the power usage of the infrastructure,” said Aaron Erwin, sales engineer at Firstco. “To realise the most efficient vertiport network, technology should be used to leverage the maximum energy management benefits. Systems should not work in silos, instead energy metering data should be analysed alongside data from other sources, such as engineering and operational systems and weather sensors.”

Erwin said digital tools such as Firstco’s vertiport management system (VMS) have data integration at the heart of the platform, ensuring vertiports operate as sustainably as possible: “The power management functionality of the VMS allows vertiport operators to forecast and optimise power usage. Multiple power sources, including renewables such as solar and hydrogen, can be integrated, creating a robust power management system capable of adapting to day-to-day variations in power demand and tariffs.”

There’s more to vertiports than meets the eye, with electrical and digital systems among the most important elements of the new facilities